Do You Have an Air Tight Solution for Saving Compressed Air?

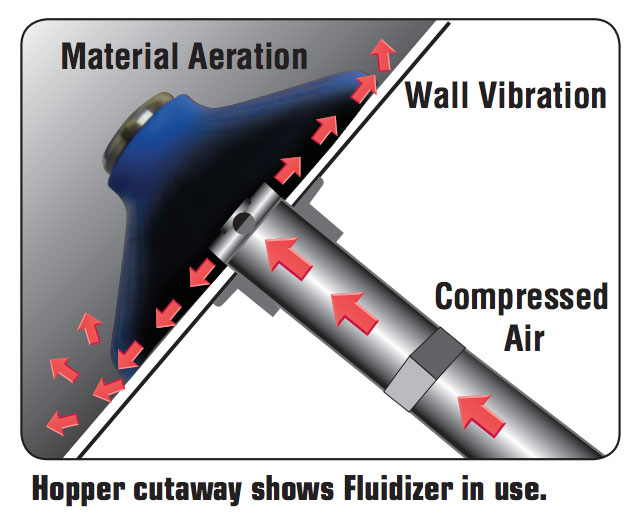

Is More Air Better for Material Discharge? Not Always. Save costly compressed air by following these tips:

Only Run Fluidizers When Silo is Discharging. Charging a hopper with air when it is a closed vessel creates holes in stored material which can prevent product from flowing properly when the discharge is opened.

Split Fluidizers into Groups or Zones. When multiple fluidizers are used in one silo, they need not operate at the same time. This consumes compressed air fast and may not speed discharge. Operate groups of fluidizers separately, for example four at a time.

Set Your PLC or Timer to Pulse the Fluidizers. The most frequent question asked is ‘How often to run a fluidizer?’ Every vessel and every product behaves differently. Set your controller to pulse with 2-3 second bursts spaced at 10-15 second intervals. Start here and fine tune as needed.

We can assist you with specific applications. Our experienced staff can provide you with fluidizer placement information, fluidizer control systems, and air consumption requirements. Read our Silo Fluidizer User Guide or installation tips and visit our website for a complete library of resources.